Understanding T Profiles, T Patti, and Stainless Steel T Patti – A Comprehensive Guide

In the realm of construction and interior design, T profiles, T patti, and stainless steel T patti play a crucial role. These elements are integral to creating robust and aesthetically pleasing structures. This article delves into the details of these components, exploring their uses, benefits, and variations.

What are T Profiles?

T profiles are structural elements shaped like the letter “T”. They are widely used in construction and manufacturing due to their ability to bear heavy loads and provide structural support. The vertical section of the T, known as the web, handles shear stress, while the horizontal part, called the flange, deals with bending movements.

Applications of T Profiles

- Construction: T profiles are often used in buildings for structural support in walls, roofs, and floors.

- Industrial Machinery: These profiles provide stability and strength in various machinery.

- Railways: Used in tracks and other railway infrastructure for their durability.

- Furniture Design: In modern furniture, T profiles add a sleek and robust framework.

What is T Patti?

T patti refers to T-shaped strips or bars that are primarily used for decorative and functional purposes in interiors and construction. These strips can be made from various materials including wood, metal, and plastic.

Applications of T Patti

- Interior Decoration: T patti is extensively used in ceiling designs, wall paneling, and flooring to create visually appealing patterns.

- Partition Walls: In office spaces, T patti is used to construct partition walls, providing both support and an elegant finish.

- Door and Window Frames: These strips are also used in the framing of doors and windows for added strength and aesthetic appeal.

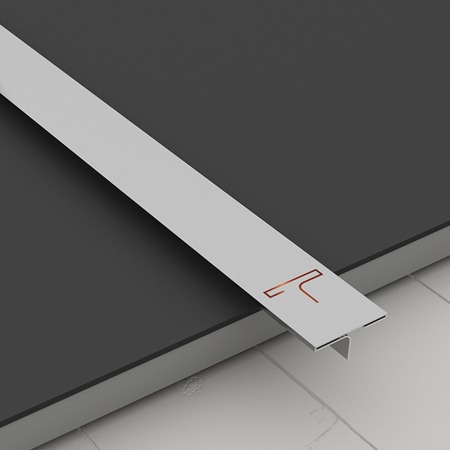

Stainless Steel T Patti

Stainless steel T patti combines the structural benefits of T profiles with the corrosion resistance of stainless steel, making it a popular choice in various industries.

Benefits of Stainless Steel T Patti

- Durability: Stainless steel T patti is known for its longevity and ability to withstand harsh environmental conditions.

- Corrosion Resistance: This material does not rust easily, making it ideal for use in moist or chemically aggressive environments.

- Aesthetic Appeal: Stainless steel provides a sleek, modern look that is highly sought after in contemporary design.

Applications of Stainless Steel T Patti

- Construction: Used in both structural and decorative aspects of buildings, providing a blend of strength and style.

- Automotive Industry: Stainless steel T patti is used in the manufacturing of vehicle parts that require both durability and a polished look.

- Marine Applications: Due to its resistance to rust, it is ideal for use in ships and other marine structures.

Types of T Profiles and T Patti

Aluminum T Profiles

Aluminum T profiles are lightweight yet strong, making them perfect for applications where weight is a critical factor. They are commonly used in window frames, signage, and lightweight structures.

PVC T Profiles

PVC T profiles are cost-effective and resistant to chemicals and moisture, making them suitable for plumbing, electrical conduit, and certain industrial applications.

Wooden T Patti

Wooden T patti is often used in interior design for its natural look and feel. It can be stained or painted to match any decor and is commonly used in flooring, wall paneling, and furniture.

Manufacturing Process of T Profiles and T Patti

The manufacturing process of T profiles and T patti involves several steps to ensure they meet the required specifications and quality standards.

Material Selection

The first step is selecting the appropriate material based on the intended application. Common materials include stainless steel, aluminum, PVC, and wood.

Cutting and Shaping

The selected material is then cut into the desired T shape using high-precision machinery. This process ensures that the dimensions are accurate and consistent.

Finishing

Once cut, the profiles and pattis undergo finishing processes such as polishing, painting, or coating to enhance their appearance and durability.

Quality Control

Finally, each piece is inspected for any defects or inconsistencies. Quality control ensures that only the best products reach the market.

Why Choose Stainless Steel T Patti Over Other Materials?

Choosing stainless steel T patti offers numerous advantages over other materials like wood or PVC:

- Longevity: Stainless steel does not degrade over time as wood might.

- Maintenance: It requires minimal maintenance compared to other materials.

- Safety: Stainless steel is non-combustible, making it safer for various applications.

- Environmental Impact: Stainless steel is recyclable, making it an eco-friendly choice.

Conclusion

Understanding the importance and application of T profiles, T patti, and stainless steel T patti is crucial for anyone involved in construction, interior design, or manufacturing. These components not only provide structural support but also contribute to the aesthetic and functional aspects of various projects.